A

transformer is the simplest of all electrical devices and this is because of

the simplicity and ease in building a transformer. A transformer is indeed very

simple in construction, yet the amount of engineering involved in maintaining

its elements of construction is vast.

The

transformer is made up of the following parts:

1. Two coils (in case of single phase

transformers)

2. Laminated core

3. Container for assembled core and

windings

4. Insulating medium

5. Bushings

These are

the main parts of a single phase transformer. In case of a three phase

transformer, there are six windings or coils in total and rest the construction

is the same as mentioned above.

LAMINATED CORE –

The

laminated core is made up of sheet steel laminations which are insulated from

each other with minimum air gap between them. The steel which is used to make

the core has high silicon content to produce high permeability and low

hysteresis loss.

Why the core is laminated?

1. To provide a continuous magnetic

path.

2. To reduce eddy current losses.

Varnishing

or deposition of oxide layer on the surface of steel is done in order to

insulate the laminations from each other.

Construction

wise on the basis of cores, transformers can be classified as:-

1. Core type

2. Shell type

CORE TYPE

TRANSFORMERS –

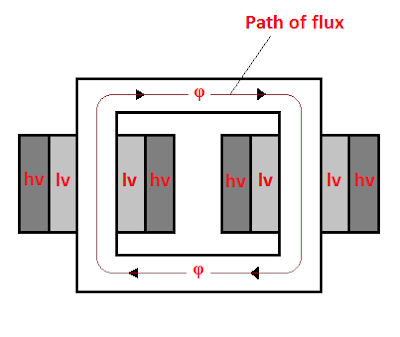

In core

type, there are two vertical legs or limbs over which the coils are wound. The

coils used are cylindrical which may be circular, oval or rectangular in shape.

|

| 2 D VIEW OF CORE TYPE TRANSFORMER |

For large

transformers, circular cylindrical type of coils is preferred.

For small

transformers, rectangular cylindrical type of coils is preferred.

The coils

are arranged concentrically. The low voltage winding is placed prior to the

high voltage winding. That means, the low voltage winding is first to be wound

on the core and then high voltage winding is wound around the low voltage

winding.

In order to insulate the cylindrical windings from the core and from

each other, insulating cylinders made of fuller board are used.

|

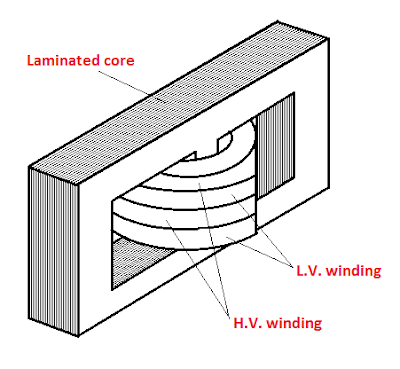

| 3 D VIEW OF CORE TYPE TRANSFORMER |

The laminations used are of various types like

L, E and U type. Laminations are stacked together just like a pile and their

joints are staggered in order to reduce the air gap between them. Larger air

gaps increases the reluctance of the core, therefore, minimum air gaps are

preferred.

Because of

the laminations and insulations, effective core area is reduced by 10%.

SHELL TYPE TRANSFORMERS –

In shell

type transformers, the windings are wound on the central limb of the core.

Other two limbs are left as it is. The purpose of these two limbs is to provide

low reluctance path.

The low voltage and high voltage windings are kept one

over the other just like a sandwich. Therefore, these type of windings are also

called disc or sandwich winding.

|

| 2 D VIEW OF SHELL TYPE TRANSFORMER |

|

| 3 D VIEW OF SHELL TYPE TRANSFORMER |

Another

question that holds importance is –

Why the cross section of the core is preferred to be circular?

This is

because circle has minimum perimeter than any other shape for a given area.

Therefore,

1. Minimum boundary means less length of

mean turns.

2. Less resistance of the winding.

3. I2R loss is reduced.

4. Volume of the conductor material

reduced and therefore cost is also reduced.

But circular

core requires large number of laminations of different sizes to be stacked

together. The solution to this problem is the stepped core arrangement, also

known as the cruciform core.

SQUARE AND STEPPED CORE CROSS-SECTIONS

This type of

core requires the size of the laminations according to the step sizes. As the

number of steps increases, the number of sizes of laminations also increases.

CONTAINER AND THE INSULATING MEDIUM –

Now this

whole assembly of core and windings is kept in a container, which is called

tank. The tank is made air tight and filled with insulating oil. Along with

insulation this oil also serves the purpose of cooling the coils of the

transformer.

What should be the properties of transformer oil?

1. Good transformer oil should be free

from any type of reagents that can react with the components of transformer.

2. The oil should be free from moisture.

Because,

presence of moisture lowers the dielectric strength of oil and it is not

desirable as the oil is used for insulation purpose.

The

transformer oil or the insulating medium is that part of the transformer which

is taken care, the most. The life of a transformer is dependent on these

insulating mediums and therefore they are selected on the basis of their high

quality and their ability to preserve that quality even after prolonged use.

Long-time

use of oil also causes Sledging. Sledging is the decomposition of oil leading

to heavy and dark coloured deposits which can clog the ducts of transformer.

Thus,

transformer oil is regularly checked and changed, if required to do so.

BUSHINGS –

Transformer

bushings are made of porcelain for small transformers and large transformers

are equipped with oil filled condenser bushings. The bushings are used for bringing

out the terminals of the windings.